Calibration Benefits

It is recommended to check and correct your fuel meters at least once a year; however, the problem with annual calibrations is that if a Weights and Measures officer stops in before you have it done, you may be out of tolerance and could incur violations that will shut you down and be quite costly. About half of our clients calibrate annually; the other half semi-annually. It’s important to note that meters can fail at any time, over-delivering individually or much more so during the blending process.

Our Semi-annual Calibration Program offers a number of benefits:

- It verifies, changes and re-verifies that your meters are delivering and functioning properly.

- It checks your slow flow blends for faulty meter overages, thereby giving you peace of mind that you are not giving away any product at your pumps at any time during the year.

- It identifies bad or faulty meters that we can replace and re-calibrate back to proper functionality.

- It lets you know how fast you are pumping and if it is time to change your pump filters.

- It tracks your data, and keeps your station data on file for viewing at any time.

- It keeps you in line with Weights and Measures tolerances and ensures you will never again have to pay for a violation for meter output failure.

Table T.2. Accuracy Classes and Tolerances for liquid Measuring Devices Covered in NIST Handbook 44, Section 3.30

| Accuracy | Application | Acceptance Tolerance | Maintenance Tolerance | Special Test Tolerance |

| 0.3 |

|

0.2% | 0.3% | 0.5% |

| 0.3A |

|

0.2% | 0.3% | 0.5% |

| 0.5* |

|

0.2% | 0.3% | 0.5% |

| 1.1 |

|

0.75% | 1.00% | 1.25% |

* For test draft < 40L 10 gal, the tolerance specified for Accuracy Class 0.5 in the table above do not apply. For these test draft, the following applies:

- Maintenance tolerances on normal and special tests shall be 20 mL plus 4 mL per indicated liter or 1 in3 plus 1 in3.

- Acceptance tolerance on normal and special tests shall be one-half the maintenance tolerance values, per indicated gallon.

1 Special test tolerance are not applicable to retail motor fuel dispensers.

** Flow rate refers to designed or makred maximum flow rate.

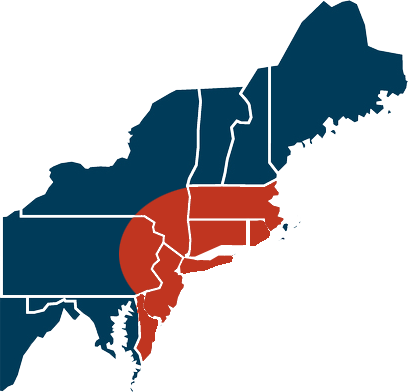

Currently servicing the following areas:

Licensed in NJ, NY, PA, DE, CT, RI and MA